Comprehensive Precision Engineering Services

From advanced laser welding to complete finishing and assembly, Efford Engineering provides a full spectrum of precision engineering services. All capabilities are housed under one roof, ensuring quality control and efficient project delivery for industrial clients across Devon and the South West.

Full-Service Precision Engineering Under One Roof

Efford Engineering offers a complete range of precision engineering services tailored to the demanding requirements of industrial clients. Our modern Exeter workshop combines advanced technology with traditional craftsmanship, enabling us to handle complex projects from initial concept through to finished components ready for installation. As an ISO 9001:2015 certified company with UKAS-calibrated inspection equipment, we guarantee consistent quality and full traceability on every job.

Having all capabilities under one roof eliminates the complexity of managing multiple suppliers, reduces lead times, and ensures quality control throughout the manufacturing process. Whether you need rapid prototypes, precision production components, or complete sub-assemblies, our experienced team delivers solutions that meet your exact specifications.

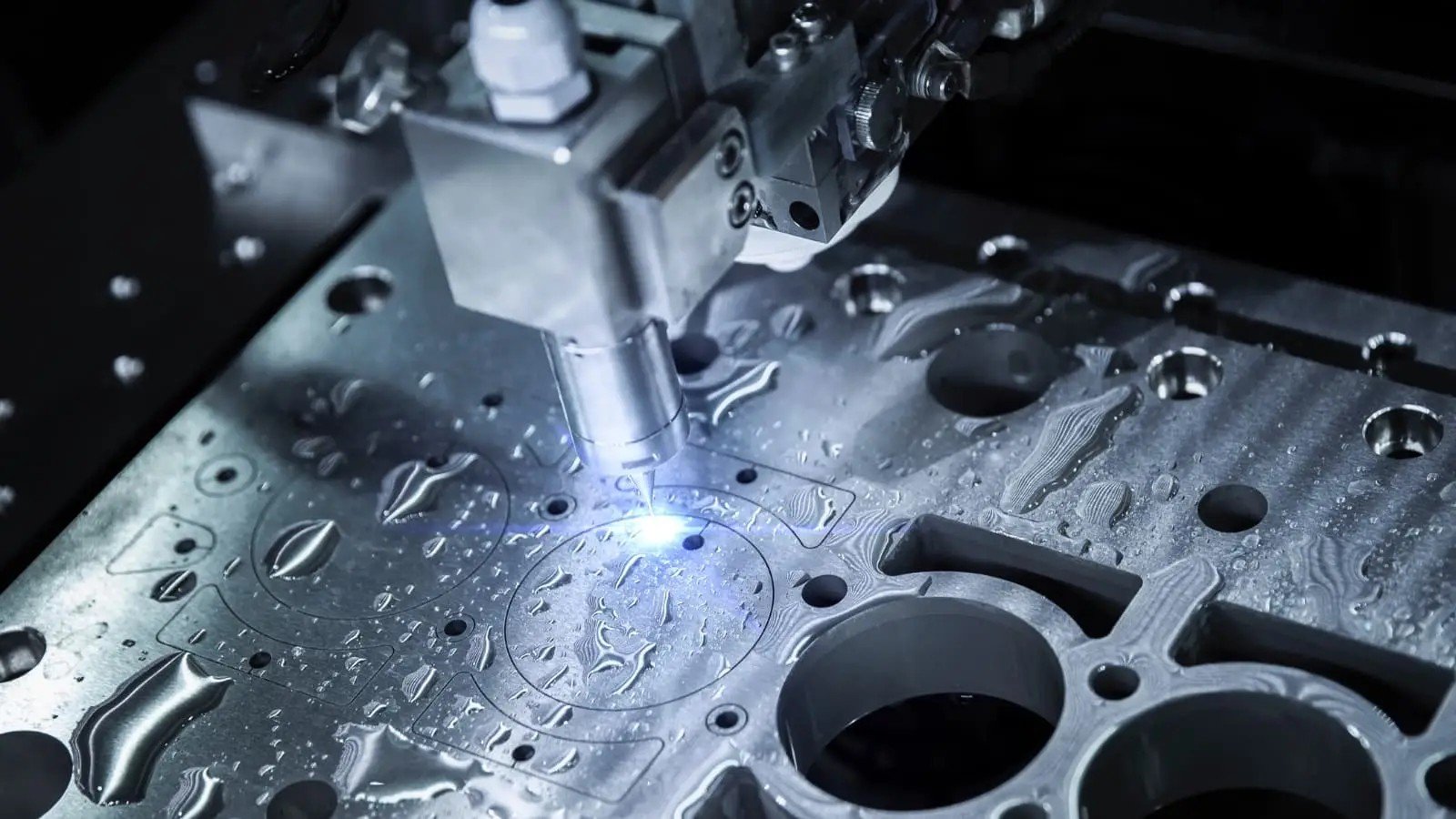

Laser Welding

Precision fusion welding with minimal heat distortion

Our advanced laser welding service uses a high-powered, focused beam to precisely fuse metals with exceptional accuracy. The concentrated energy creates minimal heat-affected zones, reducing warping and maintaining material properties. This makes laser welding ideal for thin materials, delicate assemblies, and high-specification components where traditional welding methods would cause unacceptable distortion.

- Minimal heat distortion

- Clean, precise welds

- Suitable for thin materials

- Joins dissimilar metals

- Reduced post-weld finishing

CNC Machining

3 & 4-axis milling and turning for complex components

Our CNC machining centre provides 3 and 4-axis milling and turning capabilities for manufacturing complex, high-tolerance components. Computer numerical control ensures repeatability and precision across prototype development and production runs. We work with a wide range of materials including steel, stainless steel, aluminium, brass, copper alloys, and engineering plastics.

- 3 & 4-axis capability

- High-precision tolerances

- Prototype to production

- Multiple materials

- Consistent repeatability

Manual Machining

Conventional lathe and mill work for custom parts

Traditional craftsmanship remains essential for many engineering applications. Our experienced machinists use conventional lathes and milling machines for custom components, small batches, modifications, and repairs. Manual machining offers flexibility and cost-effectiveness for simpler geometries and one-off requirements where CNC setup would be impractical.

- Custom one-off parts

- Cost-effective for small batches

- Modifications and repairs

- Flexible approach

- Skilled craftsmanship

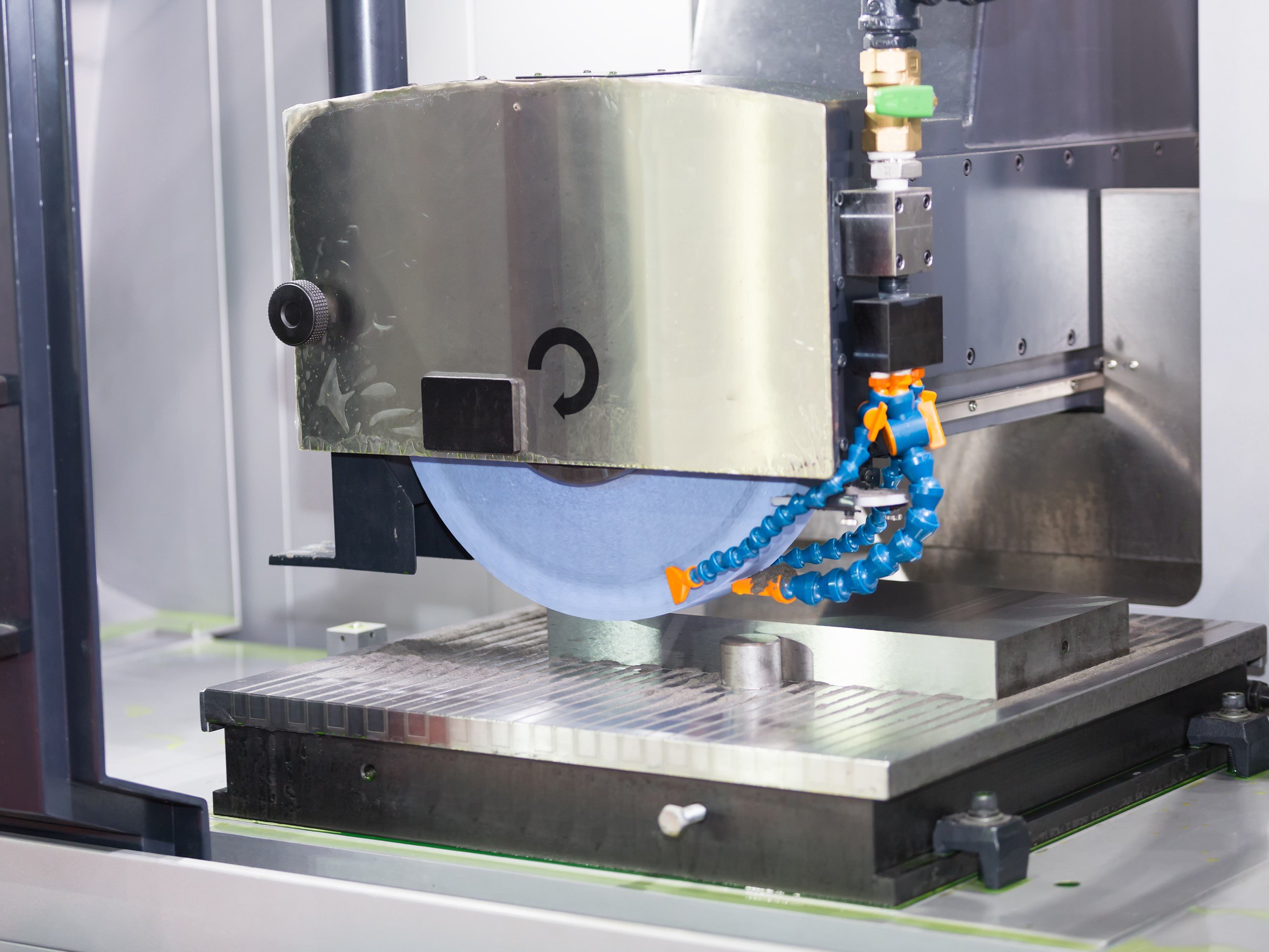

Grinding

Surface, cylindrical, and profile grinding services

Our grinding capabilities enable us to achieve exceptional surface finishes and tight tolerances on hardened materials. We offer surface grinding, cylindrical grinding (both internal diameter and external diameter), and profile grinding to meet precise specification requirements. Grinding is essential for components requiring superior finish quality and dimensional accuracy.

- Surface grinding

- Cylindrical ID/OD grinding

- Profile grinding

- Hardened materials

- Superior surface finish

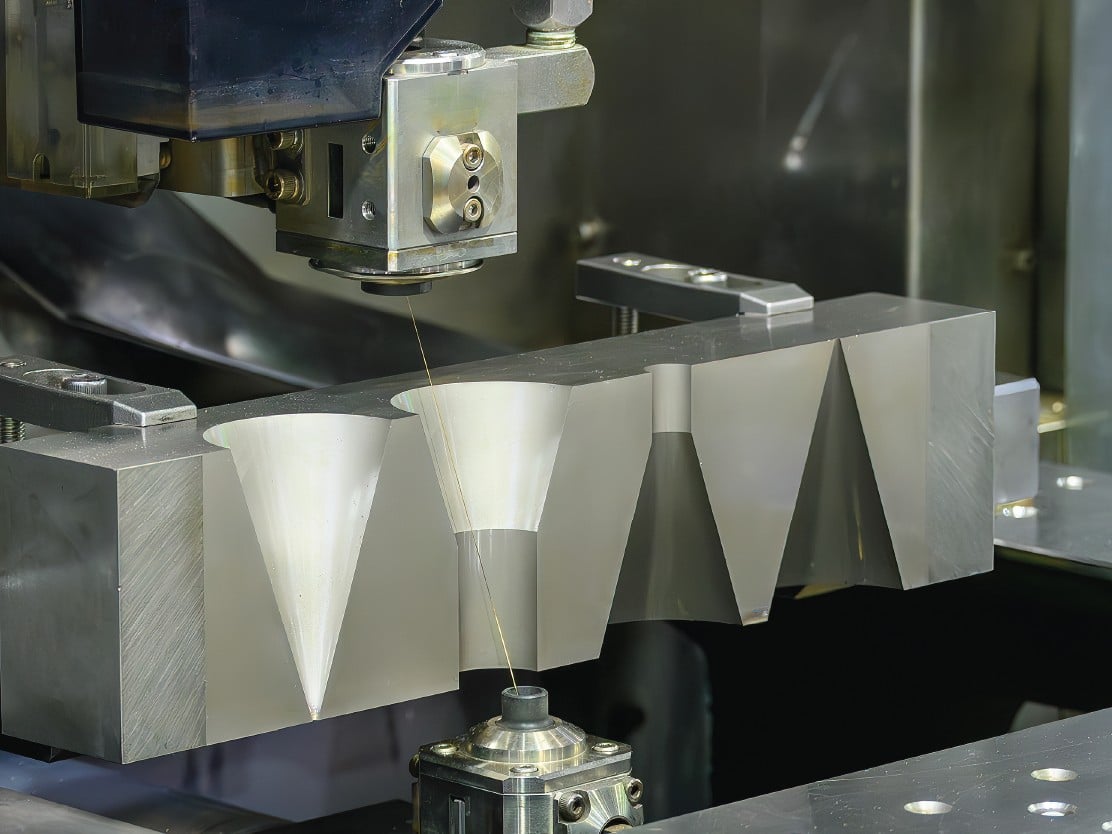

EDM (Electrical Discharge Machining)

Wire and sinker EDM for intricate geometries

Electrical Discharge Machining enables us to create intricate shapes and features that would be impossible with conventional machining. Our wire EDM and sinker EDM capabilities are ideal for hard-to-machine materials including hardened tool steels, carbides, and exotic alloys. EDM produces burr-free edges and excellent surface finishes without mechanical stress.

- Wire EDM

- Sinker EDM

- Hard materials

- Intricate geometries

- Burr-free finish

Finishing & Assembly

Complete in-house finishing and assembly services

We provide comprehensive finishing services to deliver components ready for installation. Our in-house capabilities include sandblasting for surface preparation, anodizing for aluminium protection and aesthetics, brushing for consistent surface texture, and tumbling for deburring and polishing. We also offer complete assembly services, bringing together multiple components into finished sub-assemblies.

- Sandblasting

- Anodizing

- Brushing

- Tumbling

- Final assembly

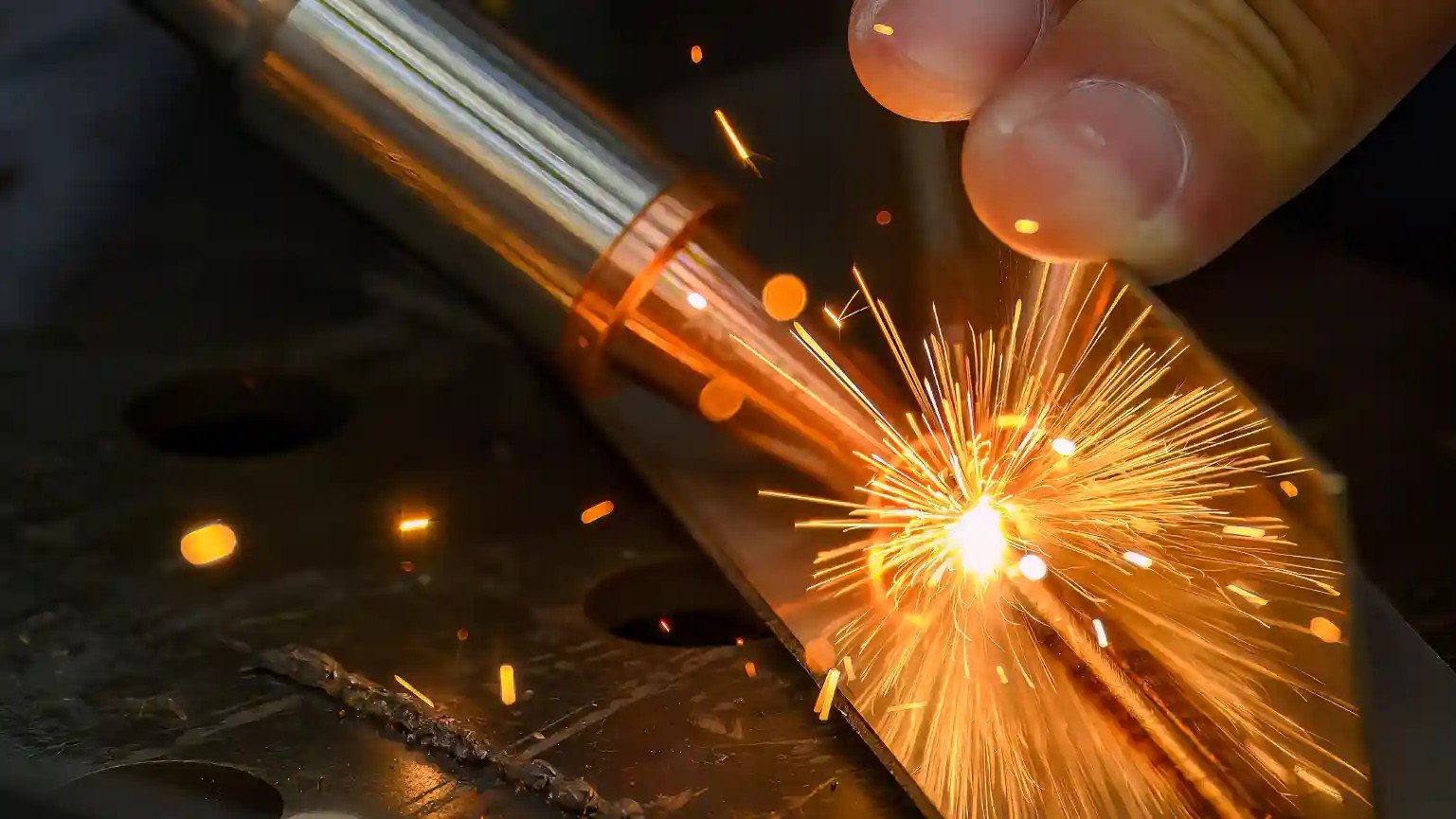

Fabrication & Repairs

General welding, repairs, and bespoke metalwork

Beyond precision machining, we offer general fabrication and repair services for industrial clients. This includes structural welding, mechanical repairs, equipment modification, and bespoke metalwork projects. Our fabrication capabilities complement our precision services, enabling us to handle complete projects from raw material to finished product.

- Structural welding

- Mechanical repairs

- Equipment modifications

- Bespoke metalwork

- Complete project handling

Our Process

From initial enquiry to final delivery, we follow a structured process that ensures quality and keeps you informed at every stage.

Enquiry & Quote

Submit your drawings and specifications. We provide a detailed quotation typically within one business day.

Review & Planning

We review requirements, confirm specifications, and plan the manufacturing approach for optimal results.

Manufacturing

Components are manufactured under our ISO 9001 quality system with in-process inspection.

Inspection & Delivery

Final inspection using UKAS-calibrated equipment, then careful packaging and prompt delivery.

Services FAQ

Find answers to common questions about our precision engineering services.

Discuss Your Engineering Requirements

Our experienced team is ready to advise on the best manufacturing approach for your project. Contact us today for a free consultation and competitive quotation.